Precision Injection Moulds for Chairs, Crates & Pallets – Built for Performance

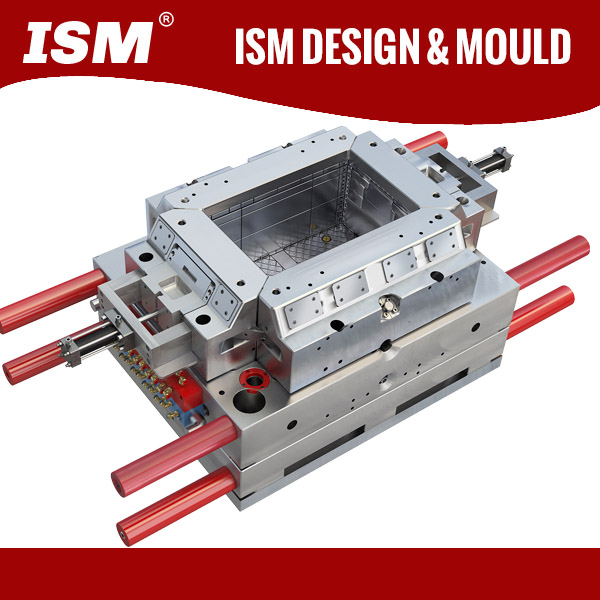

In the demanding world of plastic manufacturing, the quality and precision of the injection mould are paramount. It's the foundation upon which consistent, high-volume production of durable plastic products rests. At ISM Mould, we are specialists dedicated to designing and manufacturing robust, high-performance injection moulds specifically engineered for complex and essential items: plastic chairs, crates, and pallets.

We understand that producing these items requires more than just a mould; it requires deep expertise. Plastic chairs demand intricate designs for ergonomics and aesthetics, coupled with structural integrity. Crates need exceptional strength, stackability features, and efficient material flow. Pallets require extreme durability, precise dimensional stability for logistics, and designs that maximize production efficiency. ISM Mould possesses the proven capability to deliver moulds that excel in all these areas.

Our Core Manufacturing Expertise:

Plastic Chair Moulds: We craft moulds for a vast array of chair styles – from sleek stackable chairs to robust outdoor furniture and ergonomic office seating. Our expertise ensures flawless surface finishes, consistent wall thickness for strength and weight optimization, efficient cooling for reduced cycle times, and complex mechanisms for features like folding or stacking. We handle multi-cavity designs for high-volume production without compromising on quality.

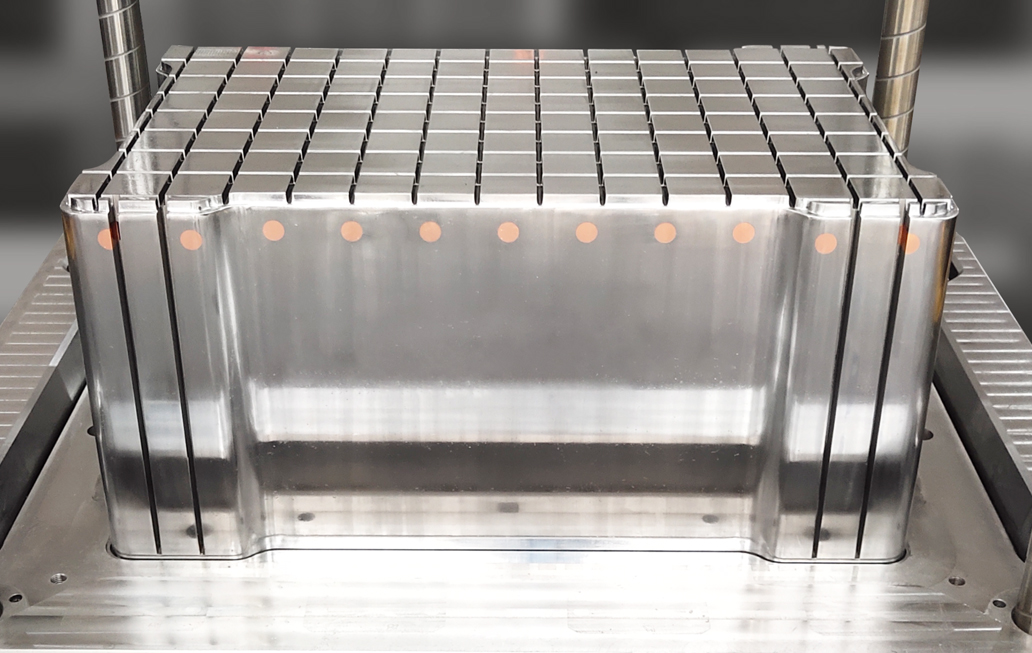

Crate Injection Moulds: Whether for agricultural produce, industrial parts, or retail logistics, our crate moulds are built tough. We focus on creating moulds that produce crates with superior impact resistance, excellent nesting/stacking capabilities, integrated handles, and optimal venting to prevent defects. We design for easy demolding and high durability to withstand the rigors of constant production cycles.

Pallet Moulds: ISM Mould manufactures heavy-duty pallet moulds designed for longevity and efficiency. Our moulds produce pallets (nestable, stackable, rackable) that meet stringent load-bearing requirements and dimensional tolerances crucial for automated logistics systems. We optimize designs for fast cycle times, minimal flash, and incorporate features for reinforced legs and decks, ensuring maximum product lifespan.

Why Partner with ISM Mould?

Engineering Excellence: Our team combines deep technical knowledge with practical experience in mould design and manufacturing for large, complex parts.

Advanced Manufacturing: We utilize state-of-the-art CNC machining, EDM, and precision grinding equipment to achieve exacting tolerances and superior surface finishes.

Material Expertise: We select and work with the appropriate high-grade tool steels (e.g., P20, H13, Stainless) based on your production volume, plastic resin, and specific part requirements, ensuring mould longevity.

Focus on Efficiency: Our designs prioritize optimized cooling channels, efficient ejection systems, and robust construction to maximize your production uptime and minimize cycle times.

Quality Assurance: Rigorous quality control processes are integrated throughout design, machining, and assembly to guarantee mould performance and reliability.

Custom Solutions: We don't just build moulds; we partner with you to understand your specific challenges and deliver tailored solutions that meet your exact production goals and budget.

Invest in Moulds Built to Last and Perform

ISM Mould is your trusted partner for high-quality, high-performance injection moulds for plastic chairs, crates, and pallets. We possess the specialized skills, technology, and commitment necessary to manufacture moulds that drive your production efficiency, ensure product consistency, and deliver a strong return on investment.

Ready to elevate your plastic manufacturing capabilities?

Leave a Reply

Your email address and tel will not be published. Required fields are marked